A coil is formed by winding 250 turns, embarking on a journey that unveils the intricacies of this fundamental electrical component. This meticulous process shapes the coil’s inductance and resistance, rendering it indispensable in a myriad of applications. As we delve into its design considerations, winding methods, testing procedures, and practical uses, the coil’s multifaceted nature will be illuminated.

From the choice of wire gauge and insulation to the selection of core material, each aspect of coil design profoundly influences its performance. Understanding these factors empowers engineers to optimize coils for specific applications. Furthermore, the techniques employed to minimize losses ensure efficient operation, maximizing the coil’s potential.

Coil Specifications

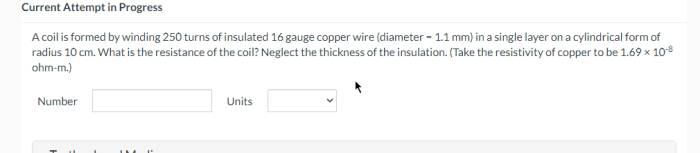

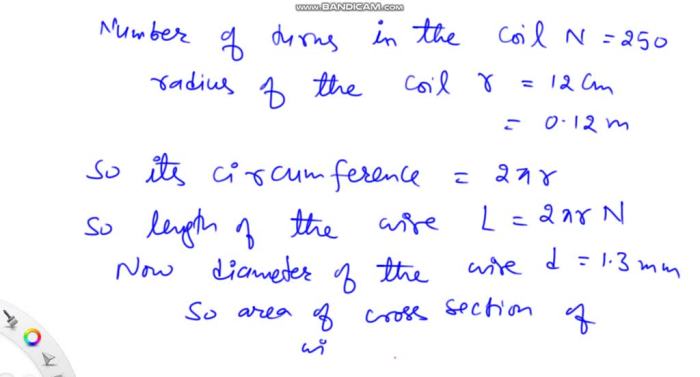

The number of turns in a coil significantly influences its electrical characteristics. In the case of a coil with 250 turns, the specific turn count affects both the inductance and resistance of the coil.

Inductance, measured in henries (H), represents the coil’s ability to store energy in a magnetic field. As the number of turns increases, so does the inductance of the coil. This is because each additional turn contributes to the magnetic field strength, leading to a greater storage capacity for magnetic energy.

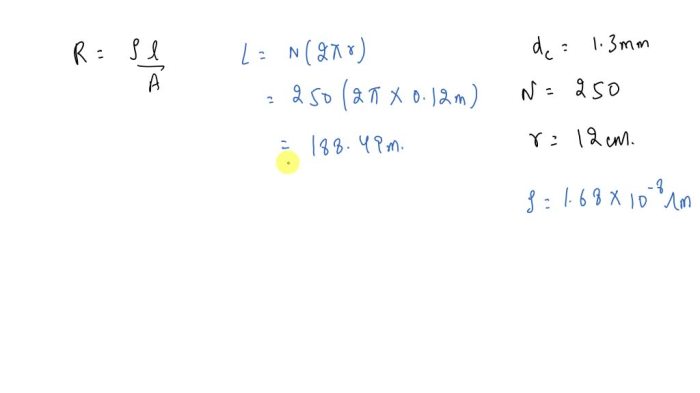

Resistance, measured in ohms (Ω), represents the opposition to the flow of electric current through the coil. The resistance of a coil is directly proportional to the length of the wire used in its construction. Since a coil with 250 turns requires more wire than a coil with fewer turns, its resistance will be higher.

Applications of a 250-Turn Coil, A coil is formed by winding 250 turns

- Inductors in electronic circuits:Coils with 250 turns are commonly used as inductors in electronic circuits, where they regulate the flow of alternating current (AC).

- Transformers:250-turn coils are employed in transformers to transfer electrical energy from one circuit to another through electromagnetic induction.

- Relays:In relays, coils with 250 turns generate a magnetic field when energized, causing the activation of switches or contacts.

Essential Questionnaire: A Coil Is Formed By Winding 250 Turns

What factors influence the choice of wire gauge for a 250-turn coil?

Wire gauge selection depends on the desired current carrying capacity, resistance, and physical dimensions of the coil.

How does core material selection affect coil performance?

Core material influences the coil’s inductance, losses, and frequency response, impacting its overall efficiency and performance.

What techniques are used to minimize losses in a 250-turn coil?

Techniques such as using high-quality wire, minimizing winding resistance, and selecting a low-loss core material help reduce losses and improve coil efficiency.